Replenishment report¶

The replenishment report is an interactive dashboard that uses manual reordering rules, lead times, and upcoming demands to forecast quantities of products that need restocking.

Reordering rules used on this dashboard are normal reordering rules, but the user benefits from a monitoring menu with extra options to manage suggestions for replenishment.

This enables users to anticipate future needs, keep less products on hand without the risk of running out, plan and consolidate orders.

Order to max¶

If a reordering rule does not forecast the product to arrive below the minimum, the replenishment cannot be triggered, because it is seen as unnecessary. However, there can be instances where a product needs to be replenished even if it is not deemed necessary, such as when an order needs to be maximized to obtain better discounts, or to save on delivery costs.

First, select one or more products by ticking the appropriate checkbox. Then, click the Replenish button and select Order to Max. Doing so creates a request for quotation (RFQ) for the first possible replenishment date for each product for the maximum specified in the reordering rule.

Horizon days¶

Horizon days determine how many days ahead Odoo checks if the forecasted quantity will drop below reordering rule’s minimum. The feature is meant to help users plan replenishment in advance, by increasing the forecasted date on the replenishment report.

Example

Setting horizon days to 7 ensures all manual reordering rules set to trigger within the next

seven days appear on the replenishment report, allowing users to review and decide which products

to order in advance.

To set horizon days, go to , and click Manual in the left sidebar. In the menu that appears, set the number of Horizon days.

Both horizon days and visibility days allow Odoo to anticipate future demand, but they work differently:

Visibility days: only checks future demand if a replenishment would have been triggered today.

Horizon days: looks ahead a specified number of days and triggers reordering rules as soon as the forecasted quantity falls below the minimum within that window — even if no replenishment is needed today.

Example

Current date: Feb 18

On hand quantity: 10

Reordering rule: Min: 5, Max 10

Vendor lead time: 1 day

8 units are needed for an SO on Feb 23. That means, on Feb 23, there will only be 2 units in stock.

Without horizon days

The demand appears on the replenishment report only on Feb 22, one day before the delivery date.

Forecasted date: Feb 19 (current date + vendor lead time)

With horizon days (4 or more days)

Odoo considers demand up to Feb 23 as relevant today (Feb 18)

The need for 8 more units appears immediately in the replenishment report

Forecasted date: Feb 23 (current date + vendor lead time + horizon days)

Replenishment information¶

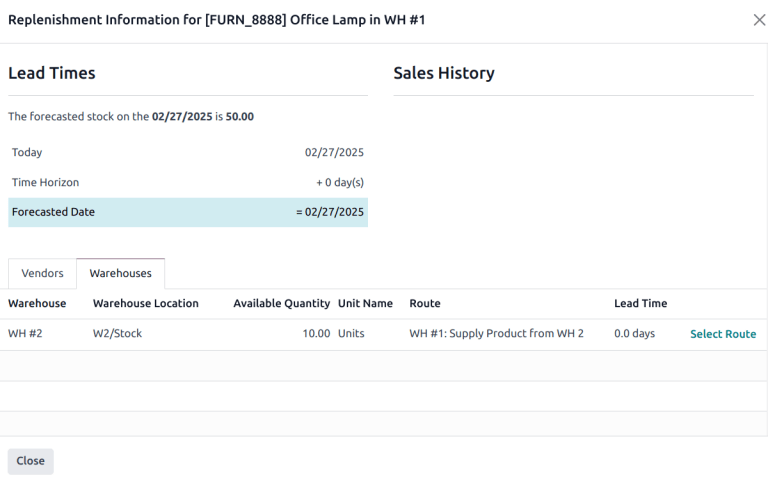

In each line of the replenishment report, clicking the (info) icon opens the Replenishment Information pop-up window, which displays the lead times and forecasted date.

For detailed information on how to use this feature for replenishment, go to the Just in time logic section.

Select a warehouse¶

If a warehouse’s replenishment method is resupply from another warehouse, check for available product quantities in other warehouses by opening the Replenishment Information pop-up window. Warehouses that can replenish the stock are listed under the Warehouses tab, and the Available Quantity shows the on-hand stock in each warehouse.

After selecting a sourcing warehouse, click Select Route Order button is clicked, the reordering rule will revert to its preferred route (Buy or Manufacture).

See also